The rapid growth of semiconductor materials for nanoscale applications has driven the development of high-quality crystalline thin films crucial for advanced technologies. Key methods like chemical vapor-phase deposition (CVD) and its variations—MOVPE, PECVD, and MBE—are now essential in the electronics industry. Over the past thirty years, advancements in these techniques have facilitated the production of epi-wafers for various semiconductor applications, including CMOS, HEMT, RF, power, and laser technologies.

The Computer Aided Design (CAD) software can help to realize the deep insight with atomistic scale solution and the proper understanding of the microscopic issues and challenges associated with these reactors based epitaxial growth processes.

The TNL-EpiGrow simulator provide real-time reactor growth conditions through simulation for accurate trial experiments, reducing labor, conserving gases, lowering processing costs, and identifying defects.

The TNL-EpiGrow simulator supports multiple epitaxy processes for analyzing vapor phase epitaxy methods like CVD, PECVD, MOCVD, and MBE. It aids in optimizing growth processes for semiconductors, insulators, metals, superconductors, and magnetic materials.

TNL-Optimizer enables design of experiments (DOE) to fine-tune input parameters for producing high-quality crystalline films with minimal defects, enhancing the epitaxial growth of semiconductors, oxides, insulators, metals, and superconductors.

Epitaxial Growth processes inbuilt in the TNL-EpiGrow simulator are:

Graphical User Interface (GUI)

Windows based Application

Various Semiconductor Materials Database

Thermal chemical kinetics

Plasma enhaced chemical kinetics

Users' defined input growth conditions

To handle various gas phase kinetics

To handle various surface phase kinetics

Import users' specific gas & surface phase kinetics

Inbuilt precursor & carrier gases database

kMC based Adsorption, hopping & desorption rates

Reactor geometry parameters as input

molecular beams with various Knudsen cells

Impact of Schwoebel-Enrich barrier energy

Impact of incorporation barrier energy

Impact nearest neighbor energy

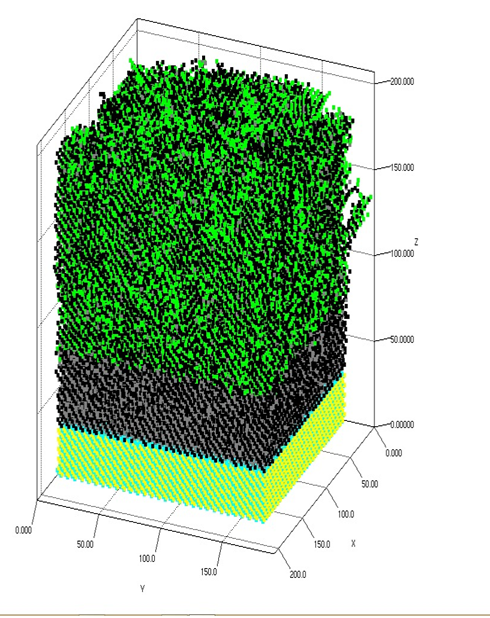

Mapping each & every atom in each monolayer

Point Defects density with location on lattice

Line Defects density in lattice

Stacking Fault density in lattice

Surface profiles i.e. Roughness

Strain measurement

Lattice Parameter

Optimization of input parameters

Optimization of chemical kinetics

Reduction in waste during experimentation

Ability to deal with different reactive species and reactor geometries

On-line process control