Atomistic TNL Epitaxial Material Growth CAD Software accelerates CVD deposition processes by using atomistic simulations based on physics and kinetic Monte Carlo (kMC) algorithms. This approach enables real-time replication of deposition experiments without relying on continuum models or partial differential equations.

Reactor Geometry

Substrate Symmetry

Substrate Orientation

Precursors database

Carrier gases database

Flow rates

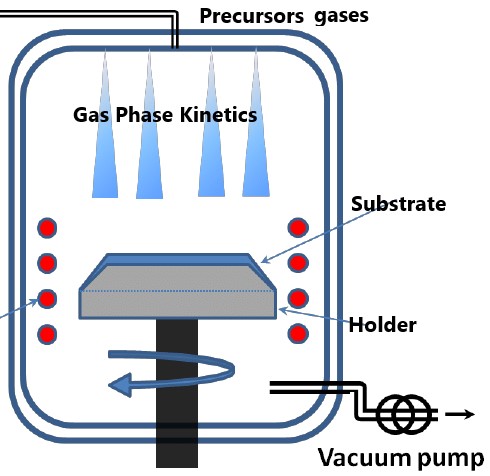

Gas phase kinetics

Surface Phase kinetics

Chamber & Substrate Temperature, Pressure

Chamber Pressure

Schwoebel-Enrich barrier

Incorporation barrier

Nearest neighbor energy

Arrehnius based chemical kinetics

Transition State Theory

Fick's law

Leonard-Jones parameters

Chapman-Enskog theory

Schmidt number

Laminar Boundary

Growth Rate

Average Surface Roughness

Lattice Parameter of each & every atoms

Average Strain

Void or Vacancy density

Interstistials density

Line defect density

Stacking Faults density

Mole fraction

Lattice Constant

Reactant gases transportation into the reaction chamber,

Reactant gases diffusion through the gaseous boundary layer to the substrate

Formation of intermediate reactants from reactant gases

Absorption of gases onto the substrate surface

Single or multi-step reactions at the substrate surface

Desorption of product gases from the substrate surface

Forced exit of undesired product gases from the system

Reliable coupled algorithms: kinetics of gas and surface phase reactions and the kinetic Monte Carlo (kMC) method

Computationally efficient to enhance the CVD deposition process and to analyze the thin film morphologies at the atomistic scale

Closed-loop operational strategy to enhance the quality of films and minimize the variability between batches due to drift

In-depth atomistic insights and understanding of chemical kinetics, including adsorption, hopping, diffusion, and desorption, with diverse output data across various input conditions

Optimize chemical kinetics and deposition parameters, including precursor and carrier gas flow rates, to improve the quality of thin films and epitaxial growth.

Reducing manpower and costs speeds up the transition from development to production for new growth processes

More details